Moulding And Casting Of Connecting Rod . a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. The assessment of adequate fibres positioning. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. the mould is developed for complying to several requirements, i.e. Connecting rod is an integral.

from www.zhycasting.com

the mould is developed for complying to several requirements, i.e. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. Connecting rod is an integral. The assessment of adequate fibres positioning. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder.

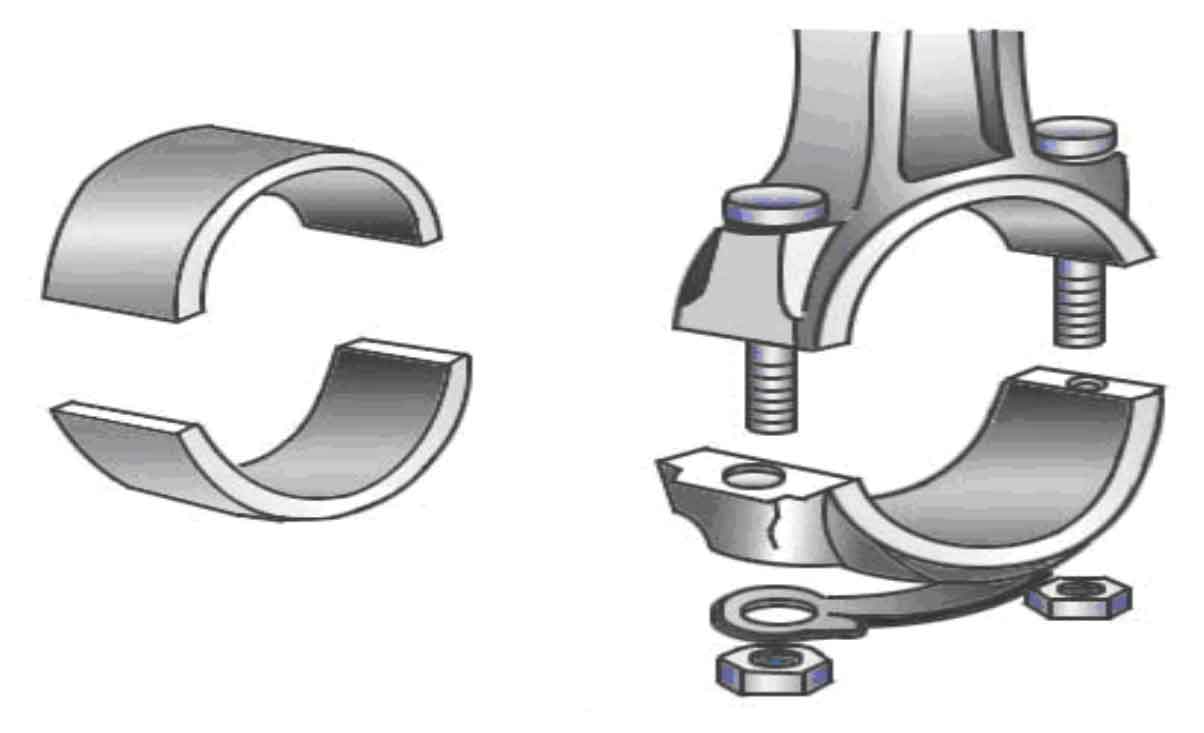

Main structure of automobile connecting rod ZHY Casting

Moulding And Casting Of Connecting Rod Connecting rod is an integral. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. the mould is developed for complying to several requirements, i.e. The assessment of adequate fibres positioning. Connecting rod is an integral. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled.

From www.youtube.com

Introduction to Connecting Rod YouTube Moulding And Casting Of Connecting Rod The assessment of adequate fibres positioning. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. Connecting rod is an integral. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. connecting rod is the engine component used for joining and transferring force from. Moulding And Casting Of Connecting Rod.

From www.enginelabs.com

Connect The Rods IBeam and HBeam Connecting Rods Explained Moulding And Casting Of Connecting Rod The assessment of adequate fibres positioning. the mould is developed for complying to several requirements, i.e. Connecting rod is an integral. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. a typical. Moulding And Casting Of Connecting Rod.

From www.newkidscar.com

Connecting Rod Diagram Car Anatomy Moulding And Casting Of Connecting Rod a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled.. Moulding And Casting Of Connecting Rod.

From www.mdpi.com

Materials Free FullText The New Technology of Die of Moulding And Casting Of Connecting Rod the mould is developed for complying to several requirements, i.e. The assessment of adequate fibres positioning. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. Connecting rod is an integral. a. Moulding And Casting Of Connecting Rod.

From www.albonplc.com

Albon Connecting Rods Essex Moulding And Casting Of Connecting Rod a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. Connecting. Moulding And Casting Of Connecting Rod.

From www.slideshare.net

manufacturing of connecting rod Moulding And Casting Of Connecting Rod connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. Connecting rod is an integral. The assessment of adequate fibres positioning. the mould is developed for complying to several requirements, i.e. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging. Moulding And Casting Of Connecting Rod.

From www.theengineerspost.com

The Engineers Post Blog for Engineers Moulding And Casting Of Connecting Rod connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. The assessment of adequate fibres positioning. this paper will take the machining technology of connecting rod and the. Moulding And Casting Of Connecting Rod.

From www.theengineerspost.com

Connecting Rods Parts, Types, Functions, Applications [PDF] Moulding And Casting Of Connecting Rod the mould is developed for complying to several requirements, i.e. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. Connecting rod is an integral. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. a typical permanent mold design with a vertical. Moulding And Casting Of Connecting Rod.

From www.zhycasting.com

Automobile connecting rod ZHY Casting Moulding And Casting Of Connecting Rod Connecting rod is an integral. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. The assessment of adequate fibres positioning. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. every vehicle that uses an internal combustion. Moulding And Casting Of Connecting Rod.

From www.chevyhardcore.com

XBeam Connecting Rods Lunati's New Design For Extreme Applications Moulding And Casting Of Connecting Rod the mould is developed for complying to several requirements, i.e. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. The assessment of adequate fibres positioning. Connecting rod. Moulding And Casting Of Connecting Rod.

From www.youtube.com

Connecting rod manufacturing process YouTube Moulding And Casting Of Connecting Rod Connecting rod is an integral. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for. Moulding And Casting Of Connecting Rod.

From www.precisiontool-oilcity.com

Connecting Rod Machining Precision Tool Oil City Moulding And Casting Of Connecting Rod connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. Connecting rod is an integral. this paper will take the machining technology of connecting rod and the corresponding furniture design in. Moulding And Casting Of Connecting Rod.

From www.youtube.com

8 Tips For Installing Connecting Rods Integrated Engineering YouTube Moulding And Casting Of Connecting Rod the mould is developed for complying to several requirements, i.e. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. The assessment of adequate fibres positioning. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. a typical permanent mold. Moulding And Casting Of Connecting Rod.

From slidetodoc.com

DESIGN AND ANALYSIS OF CONNECTING ROD WITH DIFFERENT Moulding And Casting Of Connecting Rod every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. connecting rods are traditionally manufactured using mould casting method which has high moulding cost and requires highly skilled. a typical permanent mold. Moulding And Casting Of Connecting Rod.

From pcmachinery2000.en.made-in-china.com

Link for Die Casting and Injection Molding Machines/Casting/Machining Moulding And Casting Of Connecting Rod a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. The assessment of adequate fibres positioning. connecting rod is the engine component used for joining and transferring force from piston. Moulding And Casting Of Connecting Rod.

From www.researchgate.net

Upper and lower die with connecting rod CAD models Moulding And Casting Of Connecting Rod every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. the mould is developed for. Moulding And Casting Of Connecting Rod.

From www.dragzine.com

Connect The Rods IBeam and HBeam Connecting Rods Explained Moulding And Casting Of Connecting Rod The assessment of adequate fibres positioning. every vehicle that uses an internal combustion engine requires at least one connecting rod per cylinder. a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. the mould is developed for complying to several requirements, i.e. connecting rod is. Moulding And Casting Of Connecting Rod.

From www.zhycasting.com

Cast automobile connecting rod ZHY Casting Moulding And Casting Of Connecting Rod a typical permanent mold design with a vertical parting line to cast connecting rods and covers for forging presses of ductile. connecting rod is the engine component used for joining and transferring force from piston to the crank shaft. this paper will take the machining technology of connecting rod and the corresponding furniture design in the. Connecting. Moulding And Casting Of Connecting Rod.